Main spindle (Z1 / S1 / C1)

| Max. bar capacity |

mm |

4 |

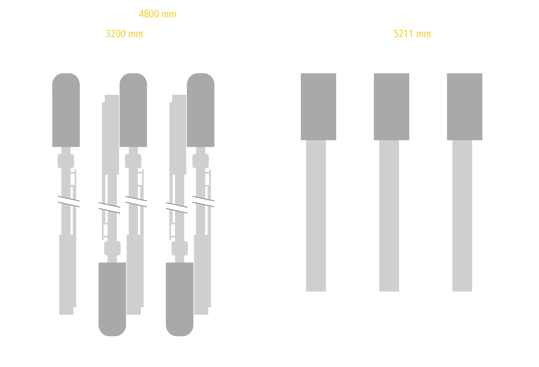

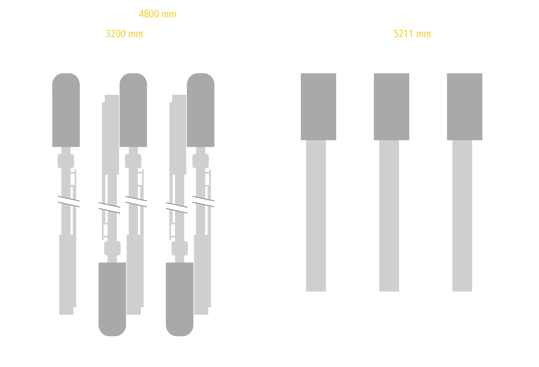

| Standard workpiece length with fixed guide bush |

mm |

28 |

| Spindle rotation speed |

t/min |

0-16000 |

| Spindle power (nominal/max) |

kW |

1/2 |

| Torque (nominal/max) |

Nm |

0.65/2 |

Guide bush holder (X1 / Y1 / S11)

| Number of tool positions on guide bush |

|

7 |

| Turning tool section |

|

8x8 |

| Positions for radial rotating tools (option) |

|

2 |

| Rotating tool speed of rotation |

t/min |

8000 |

| Rotating tool power |

kW |

0.5 |

End attachment and counter spindle (X4 / Y4 / Z4 / S4)

| Number of tool positions |

|

3x ∅ 16 |

| Positions for rotating tools |

|

3 |

| Max. bar capacity |

mm |

4 |

| Insertion length of workpiece into counter spindle |

mm |

26 |

| Spindle rotation speed |

t/min |

0-16000 |

| Spindle power (nominal/max) |

kW |

1/2 |

| Torque (nominal/max) |

Nm |

0.65/2 |

| Counter spindle ejector stroke |

mm |

10 |

Secondary operation

| Number of tool positions |

|

2x ⌀ 16 |

| Total number of basic machine tools |

|

12 |

| Operation/secondary operation tool distribution |

|

10/2 |

General specifications

| Max. length |

mm |

1800 |

| Length with LNS Tryton 3m |

mm |

5900 |

| Max. width |

mm |

650 |

| Height (without signalling lamp) |

mm |

1575 |

| Spindle height |

mm |

1150 |

| Weight |

kg |

700 |

| Cutting oil tray capacity |

l |

45 |

| Coolant pump power |

kW |

0.18 |

| Colours: RAL 9006 grey, RAL 9011 graphite black |

|

|

| CE/CEM certified |

|

|

Basic machine equipment

| Fixed guide bush + oil filter |

✓ |

| Front platten rotating tool motor |

✓ |

| C1 axis |

✓ |

| Polygon operation (and gear hobbing) function programming |

✓ |

| Thread milling device |

option |

| Gear hobbing device |

option |

| Radial drills |

option |

| Adjustment of S4 counter spindle end of clamping |

✓ |

| Pneumatic ejection of workpiece + air/oil cleaning of collet |

✓ |

| Automatic centralised lubrication cycle |

✓ |

| Beacon (1 colour) |

✓ |

| Fire extinguisher interface |

✓ |

FANUC numerical control

| Control type |

Fanuc 0i-TD |

| Encoder/axis motor technique |

sériel absolu |

| Motor type (axes/spindles) |

asynchrone/synchrone (AC) |

| Axis resolution |

0.0001 mm |