Disclaimer

General

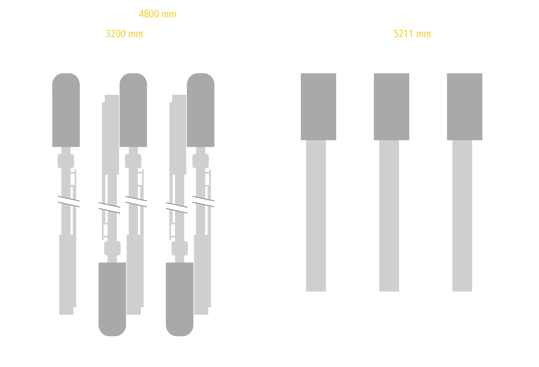

You have now reached the website of Tornos SA, a Swiss company located at Rue Industrielle 111, 2740 Moutier. The subject of this website is the Tornos SwissNano product

Contract of use

This site is subject to a contract of use, signed by Tornos SA and the visitor to the website. The user states that he agrees to the following clauses when he gains access to and uses the site, documents and any other information contained therein. If the user does not agree to this contract, then he must immediately leave this website.

Use of the website and information

The entire Tornos SwissNano website (texts, data, pictures, photos, graphs, diagrams, videos, animations, press releases, annual reports, technical specifications, product descriptions etc.), is covered by copyright and trademark law. You may download or print hard copies of pages and/or parts of the website, provided you do not delete any information relating to copyright or to rights of ownership. Downloading or any other form of copying software or information featured on the Tornos website does not give you any right to these. You will not be allowed to reproduce, transmit in any manner whatsoever, modify or use the Tornos website for publicity or commercial purposes, nor will you be allowed to create any links to the latter without the prior written approval of Tornos. It is expressly prohibited to use all or part of the information in contravention of these clauses and the law, and such use may give rise to penalties under civil and criminal law.

Guarantee relating to information supplied via the website

Although Tornos will do its utmost to ensure the quality of the information supplied, it may happen, as a result of the ongoing development of Tornos products and constant adaptation to market trends, that some data given on the Tornos website may contain certain inaccuracies of any nature, both in form and content (especially with respect to updates). All this information, direct or indirect advice, technical specifications and opinions are therefore supplied without any warranty whatsoever, whether express or implied. The user must contact a Tornos specialist to obtain additional information regarding his specific circumstances.

Website links

The Tornos SwissNano website may link up to other websites, but Tornos will not assume or accept any liability regarding the content, products, services or other items offered via these latter sites.